SCAN-TO-BUY SOLUTIONS

Save even more time by scanning the QR code on your Cat hose to order the exact hose you need on Parts.cat.com. The Cat part number identifies the hose assembly components and build specifications.

- Step 1: Scan the code on your Cat hose assembly.

- Step 2: Add the part to your cart directly on Parts.cat.com.

- Step 3: Choose local branch store pickup, shipment or other flexible delivery options available on Parts.cat.com.

- Step 4: Review and place your order.

- Step 5: Receive the part when and where you need it.

Know your Cat part number? Head directly to Parts.cat.com

Shop now

Ordering your Cat hose assembly has never been so easy!

ORDER ON CAT® CENTRAL

Order your Cat hose, scan and shop for your asset instantly, and find answers to repair and maintenance questions directly on the Cat Central mobile app.

ORDER ON PARTS.CAT.COM

Shop by category, part number or serial number to find the parts you need to repair and maintain your equipment.

ORDER FROM YOUR TOROMONT CAT BRANCH

Contact your branch and share the Cat hose part number(s) you need. We’ll then create an exact replacement hose using Genuine Cat parts to Caterpillar OEM specifications.

BRANCH SOLUTIONS

Sometimes a human connection is what you need. We can build any hose assembly for any machine in as little as 30 minutes. Our versatile hose assembly product line supports mixed fleets and various industry applications. Our Cat certified technicians are trained to build the proper and safe hose.

- Step 1

Provide us with the Cat hose part number(s) you need, either in person or over the phone.

- Step 2

We will build an exact replacement hose using genuine Cat parts to original Caterpillar OEM specifications.

- Step 3

Fast turnaround and quick delivery will get your equipment back up and running.

Any hose. Any machine. Ready in as little as 30 minutes.

Our Cat hose service solutions are expanding daily. Please contact your Toromont Cat branch for more information about availability in your area.

REPAIR SOLUTIONS

Hose rebuild kits

Whether you’re planning a major component replacement or carrying out preventive maintenance, we can offer hose rebuild kits and advice to help you replace worn, aged or damaged hose assemblies.

Critical spares kits

Sometimes getting the part to site quickly is just not an option. Why not ask your branch to provide you with some critical spare hose assemblies so that you are ready immediately when the time comes for hose replacement? It’s an easy way to increase efficiency and maximize uptime.

DO IT MYSELF SOLUTIONS

No time to wait? Assemble your own replacement hose on site in your own shop.

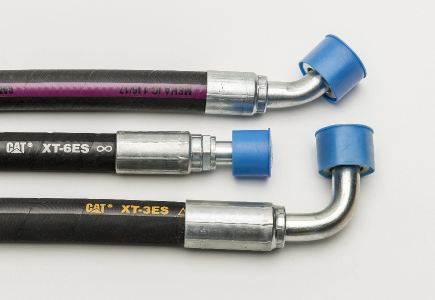

We will provide all the parts inventory, tooling and training your crew needs to turn out top-quality hose. Choose from four packages of crimping capacity, assembly technology and portability to suit the skills of your people and the needs of your operation.

STEP 1

Select Your Tooling

Choose from one of our recommended tooling packages below or build your own from our Hose Assembly tooling range.

STEP 2

Stock Inventory Profile

Provide us with your equipment fleet and we will tailor a Hose & Coupling stocking package for your needs.

STEP 3

Assembler Training

Toromont Cat offers Hose Assembler Training to ensure correct parts selection and assembly for the safest connection.

Basic Package

Crimping capabilities up to 1.25” to meet essential requirements and easy portability to job sites.

Advanced Package

Higher crimping capability of up to 3”, ensuring comprehensive coverage for hose assembly replacements.

Professional Package

Computer-controlled hose press with user-friendly menus for operation and setup, recording final crimp specifications for enhanced safety and traceability, accommodating crimping up to 3”.

Full Service Package

Crimping capabilities up to 4”, ideal for servicing large mining equipment or high-volume hose assembly production, along with Cat Crimputer Control in the Platinum package and comprehensive Hose Assembler Training.

JOB SITE SOLUTIONS

For the most time-sensitive applications, we will place a full hose shop container directly at your job site. Ideal for mine sites, large construction projects and remote locations, these fully-equipped container solutions are tailored to your operation. They get disabled equipment back to work quickly and help to keep every machine in your fleet running at peak performance.