990

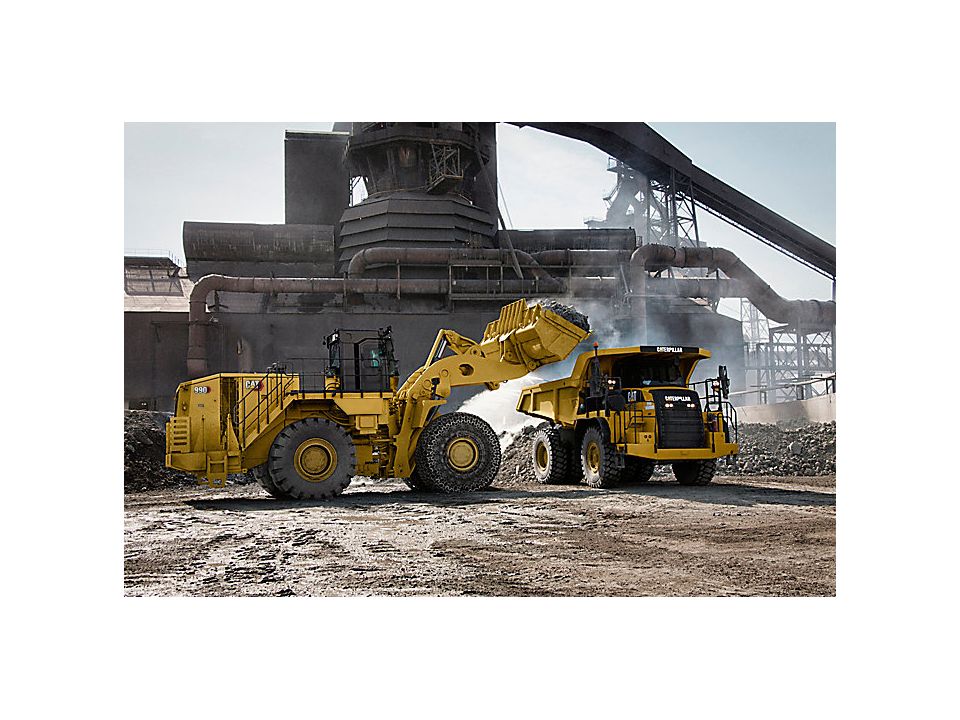

Cat® Large Wheel Loaders set the standard for optimized productivity, minimizing downtime, enhancing operator comfort, and protecting people on your jobsite through key safety features.

990

Cat® Large Wheel Loaders set the standard for optimized productivity, minimizing downtime, enhancing operator comfort, and protecting people on your jobsite through key safety features.

Specifications

Air Conditioning System

-

Air ConditioningThe air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 2.7 kg of refrigerant which has a CO2 equivalent of 3.861 metric tonnes (4.256 tons).

Axles

-

FrontFixed

-

RearTrunnion

-

Oscillation Angle8.5°

Brakes

-

BrakesISO 3450: 2011

Buckets

-

Bucket Capacities8.6 m³ – 10.0 m³ (11.25 yd³ – 13.0 yd³)

Engine

-

Engine ModelC27 Cat®

-

Rated Speed1,800/min

-

Engine Power - ISO 14396752 hp 561 kW

-

Gross Power - SAE J1995:2014766 hp 571 kW

-

Net Power - SAE J1349 - Standard Ambient699 hp 521 kW

-

Net Power - SAE J1349 - High Ambient648 hp 483 kW

-

Bore5.4 in 137.2 mm

-

Stroke6 in 152.4 mm

-

Displacement1649.5 in³ 27.03 l

-

Peak Torque - 1,200 rpm2624 lb/ft 3557 N·m

-

Torque Rise18 % 18 %

-

EmissionsU.S. EPA TIer 4 Final and EU Stage V emission standards or U.S. EPA Tier 2 and EU Stage II equivalent

Hydraulic Cycle Times

-

Rack Back4.3 s 4.3 s

-

Raise8.2 s 8.2 s

-

Dump2.9 s 2.9 s

-

Lower3.7 s 3.7 s

-

Lower Float Down3.6 s 3.6 s

-

Total Hydraulic Cycle Time - Empty Bucket13.8 s 13.8 s

Hydraulic System - Lift/Tilt

-

Lift/Tilt System - CircuitPositive flow control

-

Lift/Tilt SystemVariable displacement piston

-

Maximum Flow at 1,800 rpm (1)240 gal/min 910 l/min

-

Cylinders, Double Acting - Lift, Bore and Stroke235 mm × 1287 mm (9.3 in × 50.7 in)

-

Cylinders, Double Acting - Tilt, Bore and Stroke292.1 mm × 820 mm (11.5 in × 32.3 in)

-

Pilot SystemOpen loop and pressure reducing

-

Relief Valve Setting - Main507 psi 3500 kPa

-

Relief Valve Setting - Lift/Tilt4786 psi 33000 kPa

Hydraulic System - Steering

-

Steering System - CircuitPilot, load sensing

-

Steering System - PumpPiston, variable displacement

-

Maximum Flow at 1,400 rpm96.2 gal/min 364 l/min

-

Relief Valve Setting - Steering5004 psi 34500 kPa

-

Total Steering Angle70°

Operating Specifications

-

Operating Weight178517 lb 80974 kg

-

Rated Payload - Standard17.5 ton (US) 15.9 t

-

Rated Payload - High Lift17.5 ton (US) 15.9 t

-

Bucket Capacity Range8.6 m³ – 10.0 m³ (11.25 yd³ – 13.0 yd³)

-

Cat Truck Match - Standard773-775

-

Cat Truck Match - High Lift775-777

Service Refill Capacities

-

Fuel Tank294.3 gal (US) 1114 l

-

Cooling System54.9 gal (US) 208 l

-

Engine Crankcase20 gal (US) 75.7 l

-

Transmission29.1 gal (US) 110 l

-

Differential - Final Drives - Front71.6 gal (US) 271 l

-

Differential - Final Drives - Rear68.9 gal (US) 261 l

-

Hydraulic System Factory Fill210 gal (US) 795 l

-

Hydraulic Tank - Implement and Hydraulic Fan68.9 gal (US) 261 l

-

Hydraulic Tank - Steering and Braking34.9 gal (US) 132 l

-

NoteAll nonroad U.S. EPA Tier 4 diesel engines are required to use only Ultra Low Sulfur Diesel (ULSD) fuels containing 15 ppm (mg/kg) sulfur or less. Biodiesel blends up to B20 (20% blend by volume) are acceptable when blended with 15 ppm (mg/kg) sulfur or less ULSD. B20 should meet ASTM D7467 specification (biodiesel blend stock should meet Cat biodiesel spec, ASTM D6751 or EN 14214. Cat DEO-ULS™ or oils that meet the Cat ECF-3, API CJ-4, and ACEA E9 specification are required. For further fluid specifications and guidelines, visit: http://parts.cat.com/cda/files/3244668/7/SEBU6250-19.pdf.

Sound Performance - Standard

-

Operator Sound Level (ISO 6396:2008)65.5 dB(A) 65.5 dB(A)

-

Machine Sound Level (ISO 6395:2008)115 dB(A) 115 dB(A)

Sound Performance - Suppression

-

Operator Sound Level (ISO 6396:2008)65.5 dB(A) 65.5 dB(A)

-

Machine Sound Level (ISO 6395:2008)113 dB(A) 113 dB(A)

Transmission

-

Transmission TypeCat planetary power shift

-

Forward - 14.5 mile/h 7.3 km/h

-

Forward - 28.3 mile/h 13.3 km/h

-

Forward - 314.2 mile/h 22.9 km/h

-

Reverse - 14.9 mile/h 7.9 km/h

-

Reverse - 29.1 mile/h 14.7 km/h

-

Reverse - 315.5 mile/h 24.9 km/h

-

Direct Drive - Forward 1Lock-up disabled

-

Direct Drive - Forward 28.5 mile/h 13.7 km/h

-

Direct Drive - Forward 315.2 mile/h 24.5 km/h

-

Direct Drive - Reverse 15.4 mile/h 8.7 km/h

-

Direct Drive - Reverse 29.6 mile/h 15.4 km/h

-

Direct Drive - Reverse 316.4 mile/h 26.4 km/h

-

NoteTravel speeds based on Michelin 45/65R39 LD D2**L5 tires.

Benefits

- Cat C27 engine is built and tested to meet your most demanding applications.

- Longer engine life and improved fuel efficiency with reduced rated speed.

- Designed for longer life, rebuildability, and higher resale value.

- Maximum responsiveness with Steering and Integrated Control (STIC™).

- Moves more material more efficiently with improved power and control.

- Durable construction withstands the toughest loading conditions and multiple life cycles.

- Two engine emission options are available that meet U.S. EPA Tier 4 Final and EU Stage V emission standards or U.S. EPA Tier 2 and EU Stage II equivalent.

- Up to 10% more payload per pass on truck-loading applications with Performance Series Buckets.

- Payload increase to optimize pass on 775 trucks.

- Positive Flow Control (PFC) hydraulic system increases efficiency, bucket feel, and responsiveness with consistent performance.

- Excellent visibility to the bucket edges and work area through a Z-bar linkage.

- Planetary power shift transmission for maximum uptime.

- Convenient, responsive, electro-hydraulic controls increase operator productivity.

- Superior digging, higher bucket fill factors, reduced dig times.

- Integrated steering and transmission controls.

- Operators can check tire pressure during operation with any change sending a fault code to VisionLink®, preventing premature tire failure.

- Up to 54% fuel efficiency material per gallon of fuel (27% less fuel consumption).

- Economy mode for reduced rated engine speed and reduced fuel consumption.

- Positive flow-control hydraulics for full flow on demand at lower engine speeds.

- Engine Idle Shutdown for less fuel used while idling.

- Fully integrated electronic engine controls make your fuel go farther.

- Developed to monitor, manage, and enhance your jobsite operations.

- Payload provides accurate weighing* of the materials you are loading and hauling. Payload data is displayed in real-time to improve productivity and reduce overloading.

- Detect enhances awareness of the environment around working equipment and provides alerts to help keep people and assets safe on the jobsite.

- VisionLink wirelessly connects you to your equipment, giving you access to essential information you need to know to run your business.

- Gain valuable insight into how your machine or fleet is performing.

- Optional Advanced Productivity subscription provides comprehensive actionable information to help you manage and improve the productivity and profitability of your operations.

- 10% lower maintenance costs.

- Grouped service points.

- Electro-hydraulic controls.

- Swing-out engine compartment service doors.

- Ecology drains to prevent spilled contaminants.

- Ground level access to transmission control valves.

- Vehicle Information Management System (VIMS™) notifications to resolve problems before failure.

- Longer life, rebuildability, and high resale value.

- Standard stairway lighting.

- Left- and right-hand stairs with 45-degree angle.

- Standard Cat Vision, rear vision camera system.

- Pressurized cabin with filtered and reduced sound levels.

- Best-in-class operator comfort and ergonomics.

- Premium seat with heated and actively cooled leather, adjustable lumbar support, air adjustable bolsters on the seat and backrest, seat cushion tilt adjustment, and adjustable-length seat cushion.

- Easy-to-reach levers and controls with seat-mounted implement pod to reduce fatigue.

- Ergonomic switch placement and displays with large backlit switches, LED indicators, and ISO symbols.

- Optional heated mirrors.

- Two-position rocker switch activates the electro-hydraulic parking brake.

- Reduced vibrations from isolated cab mounts and seat air suspension.

- Automatic cab temperature controls.

- Achieve precise positioning for easy loading in tight areas with 35 degrees of steering articulation.

- Precise machine control by load-sensing hydraulic steering system.

- Designed to meet the demands of millyard applications.

- Designed for durability, ensuring availability in multiple life cycles.

- Equipped with Economy Mode to save on fuel consumption by the use of On Demand Throttle.

- Equipped with Impleller Clutch Torque Convereter (ICTC) and Rimpull Control System (RCS) to reduce tire slippage and fuel efficiency.

- Full hydraulic flow down to 1,400 engine rpm by using hydraulic flow sharing technology.

- Equipped with 45 degree angle access ladders and standard Cat Vision for enhanced safety.

- Cat forks are designed for maximum productivity and durability.

- Integrates front camera mounting location for maximum visibility to the entire fork tips during truck unloading.

- World class safety, operator comfort and efficiency in pit digging and skull handling applications.

- Efficiency of manual throttle and ergonomics of throttle lock.

- Excellent visibility to the bucket edges and work area through a Z-bar design.

- Equipped with extra heat protection to key hoses and harnesses for improved reliability.

- Best-in-class transmission for long life and consistent, smooth shifting; specifically designed for mining applications.

- Advanced filtration system for extended performance and reliability of the hydraulic system.

- Advanced Impeller Clutch Torque Converter (ICTC) and Rimpull Control System (RCS) reduce tire slippage and wear, improve fuel efficiency, and reduce cost-per-ton.

- Linkage pin joints have optional auto-lube system to ensure long life.

- Frame resists torsional shock and twisting forces.

- Heavy-duty steering cylinder mounts and axle mounting ensure increased structural integrity.

Equipment Info

NOTE

Standard and optional equipment may vary. Consult your Cat dealer for details.

OPERATOR ENVIRONMENT

Air conditioner and heater with automatic temperature control

POWER TRAIN

Brakes, full hydraulic, enclosed, oil-disc

ELECTRICAL

Alarm, back-up

OTHER

Automatic bucket tilt/lift kickouts electronically adjustable from cab

Product videos

Request a Quote